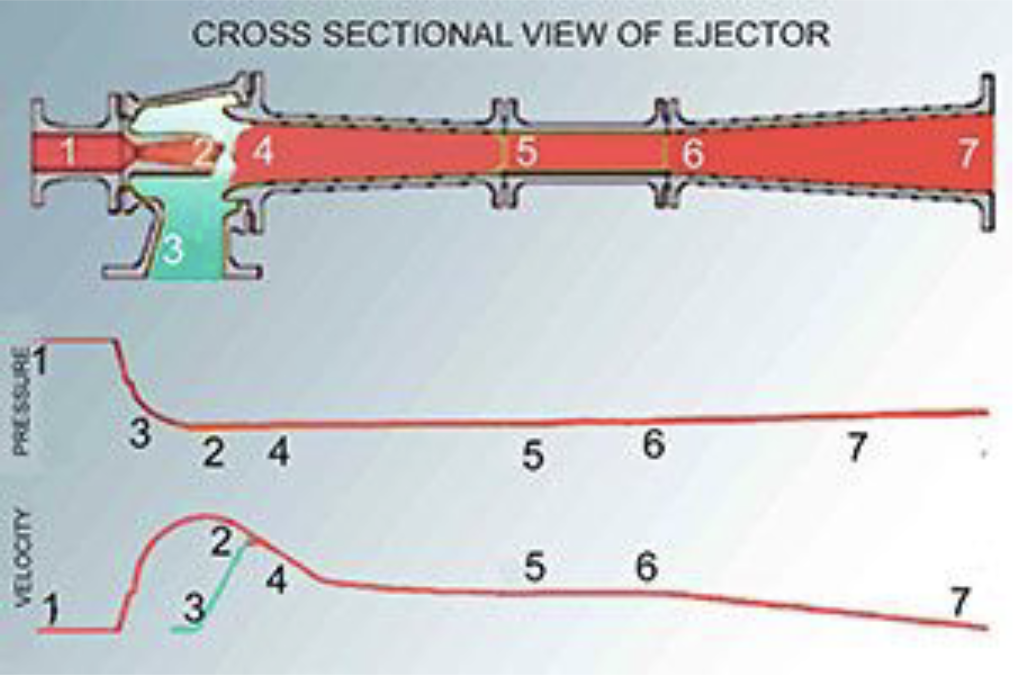

Principle of Working

-

The motive steam with high pressure and low velocity is supplied in the steam chest which exits the steam nozzle at design suction pressure and supersonic velocity. (Where velocity of the steam up to Mach number 3.0 or 4.0 is achieved by Converging & diverging nozzle).

-

The nozzle throat diameter is designed to control the amount of steam to pass through the nozzle at a given pressure and temperature.

-

And then motive stream is injected into a suction chamber. The suction chamber has the lowest static pressure (approximately equivalent to the suction pressure Ps).

-

As the combine flow of suction fluid and the motive fluid (steam) move through the converging section of the diffuser its pressure increases with decrease in its velocity.

-

At some point in the throat of the diffuser, their combined flow attains the exact speed of the sound. A stationary, sonic-speed shock wave is formed there which gives a sharp rise in absolute pressure. The shock wave in the diffuser throat changes the velocity from supersonic to sub-sonic.

-

The velocity of the mixture is sub-sonic in the diverging section of the diffuser. The increasing cross sectional area increases the pressure but further decreases the velocity.

-

The net result of these energy transformations is an increase of the absolute pressure of the mixture on discharge to several times the pressure at which it entered the ejector inlet.